Advantages

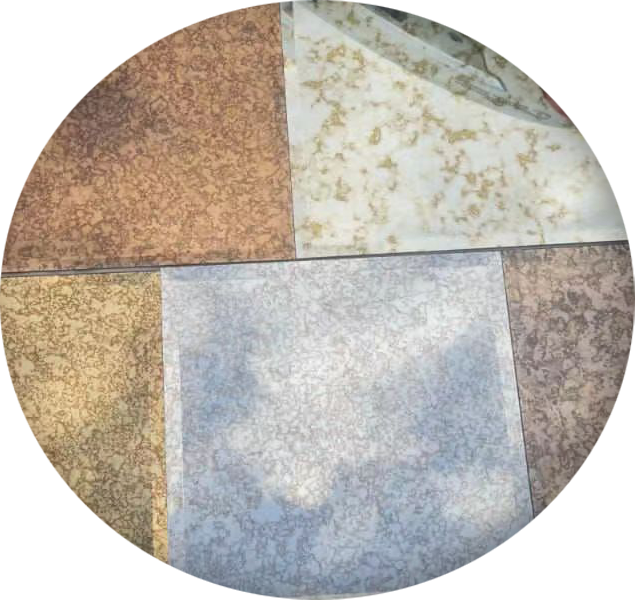

Energy-saving through good heat absorption and reflection.

Reduce the transmission of harmful UV rays.

Achieve the colorfulness of facade, minimizing fading of interior furnishings.

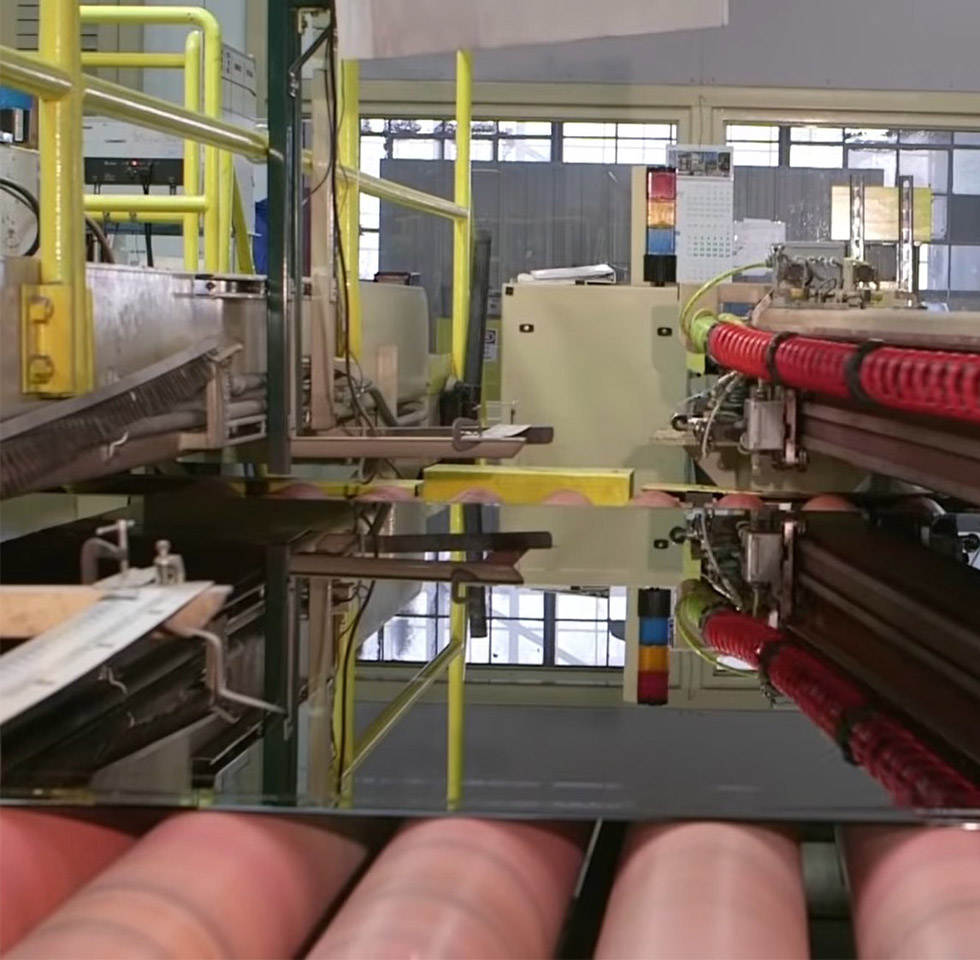

Substrate for each level of glass processing, such as cutting, fabrication, insulated glass units, shaping and edge finishing, etc.

Applications

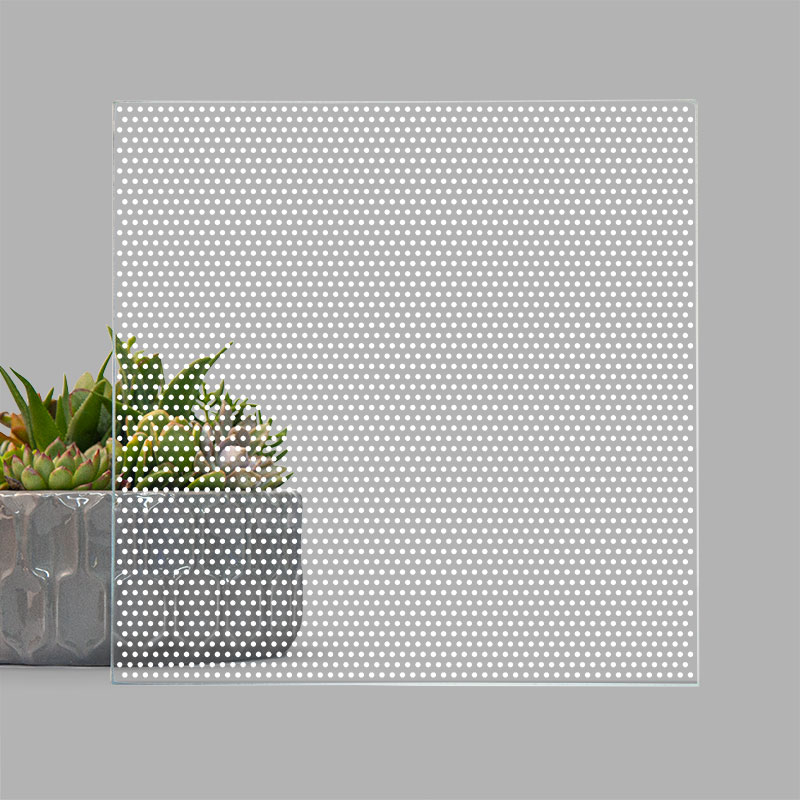

Architecture - Commercial and Civil buildings.

Automobile window shield.

Furniture and interior decoration.

Specifications

Normal thickness: 3mm~~12mm

Sizes:1650mm*2140/2250/2440mm,1830mm*2440mm, 3300/3660mm*2140/2250/2440mm etc

Ultra thin thickness: 0.8mm~~2mm

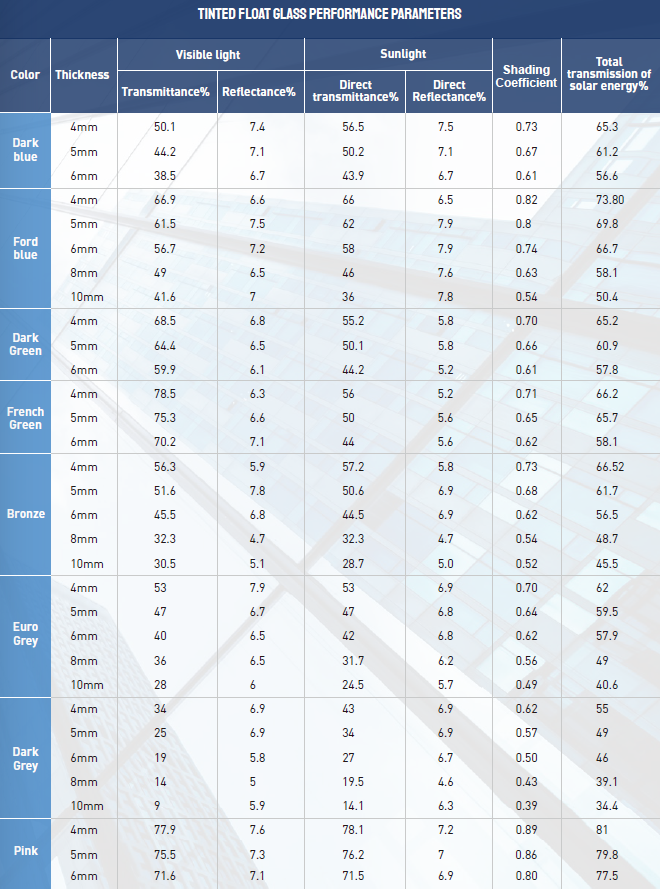

Parameters