Advantages

Five times more resistant to breakage than normal.

If the glass does break, there is far less risk of injury from broken pieces.

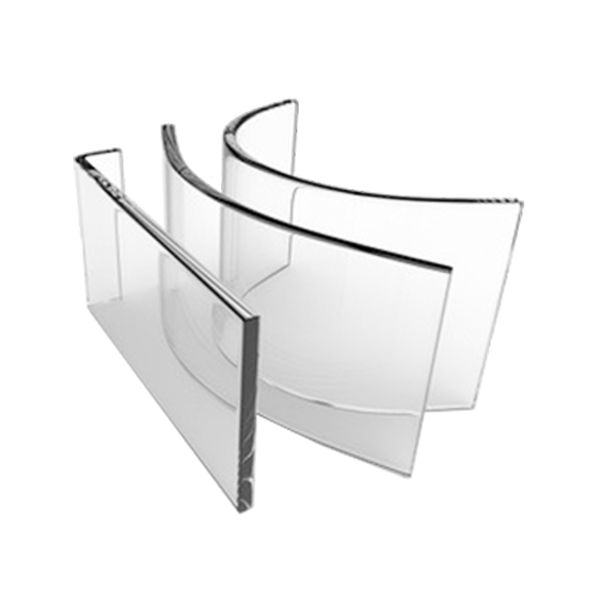

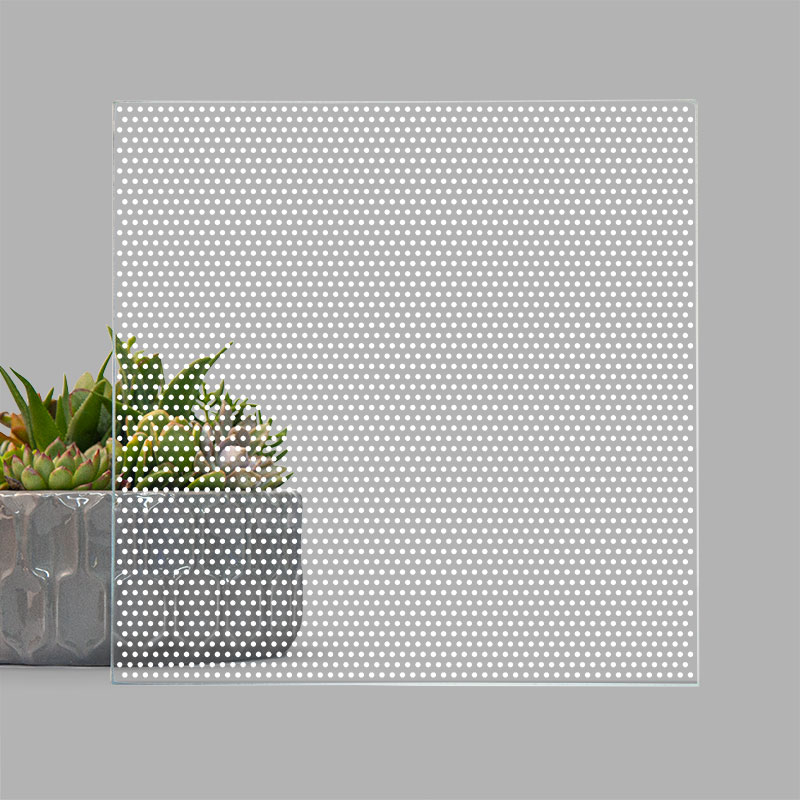

More opportunity for large areas of glazing without substituting your safety, including frameless designs such as doors, showers screens, tabletops and so on.

Applications

Airport terminals, recording studios, acoustic glazing, hotels, data – processing centers, aircraft, etc.

Structural glass,such as glass railings, glass floors, skylight glazing, roofs, curtain walls, etc.

Glass facades, windows, doors, or in any exterior applications.

Windshields of automobiles, Bulletproof glass.

Specifications

Maximum size: 3300*16000mm

(EXTRA LARGE tempered glass in the world). Minimum size: 150*150mm.

RADIUS:>=450mm.

Thickness: 3~19mm.