Advantages

Security: installed laminated glass may not be easily broken. Therefore, laminated glass provides effective defense against malicious destroy, pilferage and violent invasion.

Prevention against hurricanes and earthquakes: for the reason that fragments of broken glass still retain in its original position, laminated glass is suitable for regions subject to hurricanes and earthquakes.

Noise reduction performance: PVB membrane has good sound wave hindering property and thus, the laminated glass may effectively reduce transmission of noise.

UV shielding performance: laminated glass can substantially ward off ultraviolet (as much as over 99%), thus it helps to reduce the effect of ultraviolet on costly furniture, curtains, exhibits and other articles.

Durability: 5-10 years warranty.

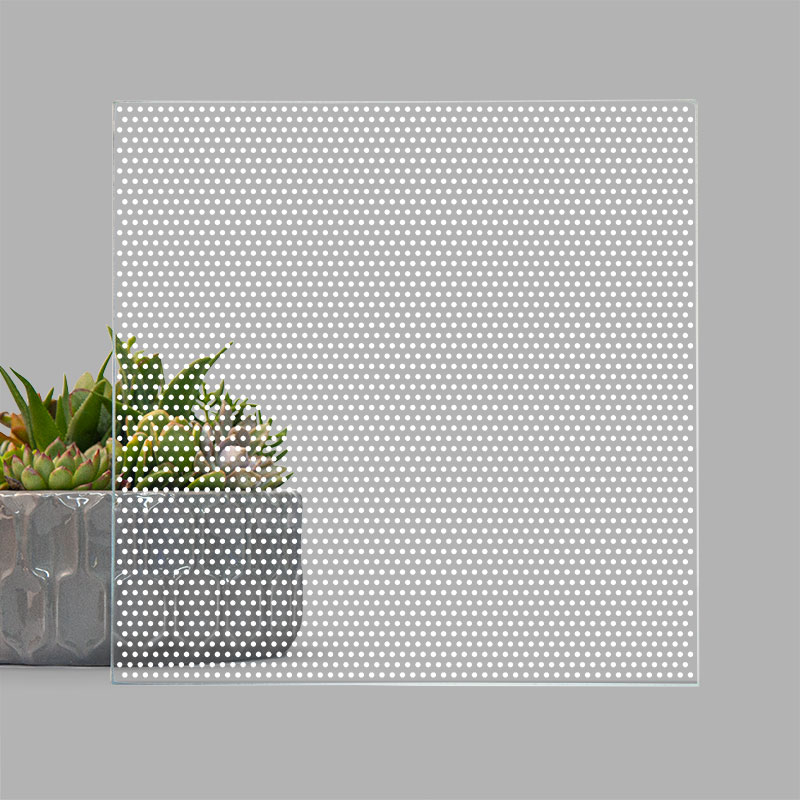

Applications

Glass facades, windows, doors, or in any exterior applications.

Windshields of automobiles , Bulletproof glass.

Airport terminals, recording studios, acoustic glazing, hotels, data–processing centers, aircraft, etc.

Specifications

Maximum dimension(mm): 3660*8000.

Minimum dimension(mm): 300*300.

Color of PVB membrane: clear, milky white, gray, blue, green and pink etc.

The thickness of PVB membrane (mm): 0.38–3.04.

Structural glass, such as glass railings, glass floors, skylight glazing, roofs, curtain walls, etc.