Advantages

Sunlight and UV rays control, Improved winter and summer thermal comfort, reduction in the amount of direct sunlight and UV rays that enter the room through the windows.

Increased energy efficiency in buildings and cost savings.

Sound insulation and improves the acoustics of the place, Helping reduce window condensation and outside noise.

Safety and security.

Applications

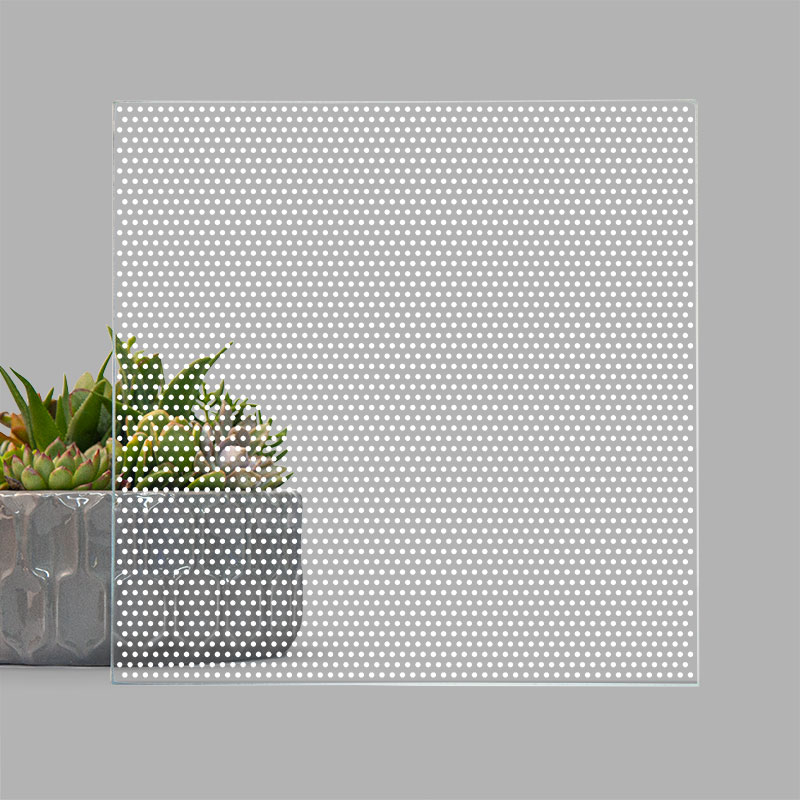

Indoors, double glazed windows, glass roofs, or in any exterior applications.

Commercial curtain walls, glass facades of high-rise structures, overhead and sloped glazing, skylights, canopies, etc.

Windshields of automobiles and trains.

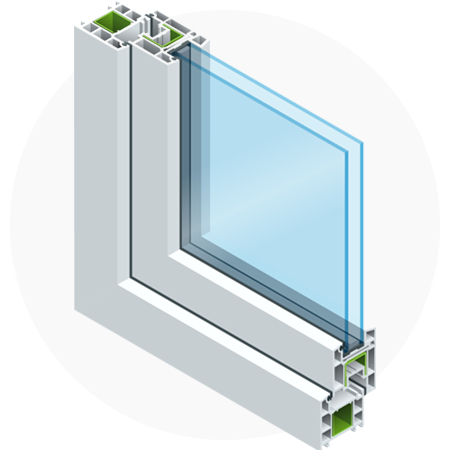

Specifications

Maximum size: 3300*16000mm (EXTRA LARGE tempered glass in the world).

Insulating gas: Air, Argon, Krypton.

Spacer: Warm edge spacer, Aluminum or Regular steel spaces, less than 25mm thickness.

Primary Seal: Kommerling/Fenzi butyl ect.

Structural Sealant:Zhijiang/Silande Structural Sealant, Depth as the client required.

* Consult your glass engineer for the IGUs performance data and more details.